Need bearings? See ISK Bearings at the 2025 Automation Show!

📌 Date: Wednesday–Saturday, 20 – 23 August 2025

📍 Venue: Taipei Nangang Exhibition Center, Hall 2, 4F

🧭 Booth: S830

In automated production, bearings are more than just rotating components—they’re critical to both efficiency and stability. ISK Bearings will present a wide range of practical solutions designed for high-temperature, corrosion-resistant, and space-constrained applications, guiding you toward the ideal selection for your needs.

Why do customers from over 50 countries choose ISK Bearings?

We’re not just a bearing manufacturer—we’re your long-term partner who understands on-site needs.

From model selection and delivery scheduling to application support, our focus goes beyond shipping—we’re here to ensure your peace of mind.

We’re equipped with a wide range of inspection tools, including automated noise & vibration testers, salt spray testers, and clearance gauges, ensuring every batch meets consistent quality standards.

“We don’t just manufacture—we know how to verify every detail.”

Based on real-world conditions—such as temperature, load, lubrication method, or space limitations—we draw on our technical expertise and application experience to help customers make better decisions from the start.

“Choosing the wrong bearing costs more than just money. We aim to help you avoid missteps from the beginning.”

We offer full customization based on your actual operating conditions—from bearing materials, structural design, and sealing options to surface treatments—helping you find the right solution for your specific needs.

Common customization directions include:

◎ Special-size bearings tailored to equipment dimensions or limited installation space

◎ Adjusting internal clearance to match lubrication methods and speed requirements

◎ Selecting materials and coatings suited to the working environment to enhance durability and performance

Our role is to help you turn usage conditions into practical, workable bearing designs.

Featured Bearings Preview

Ball Bearing

Uses rolling contact to reduce friction and distribute pressure, handling both radial and axial loads. Available in PEEK, ceramic, and stainless steel for high-speed, high-temp, or corrosive environments.

Linear Bearing

Built to metric standards with double seals and circulating steel balls. Point-contact design offers low friction, high rigidity, and stable precision—ideal for linear motion and high-load systems.

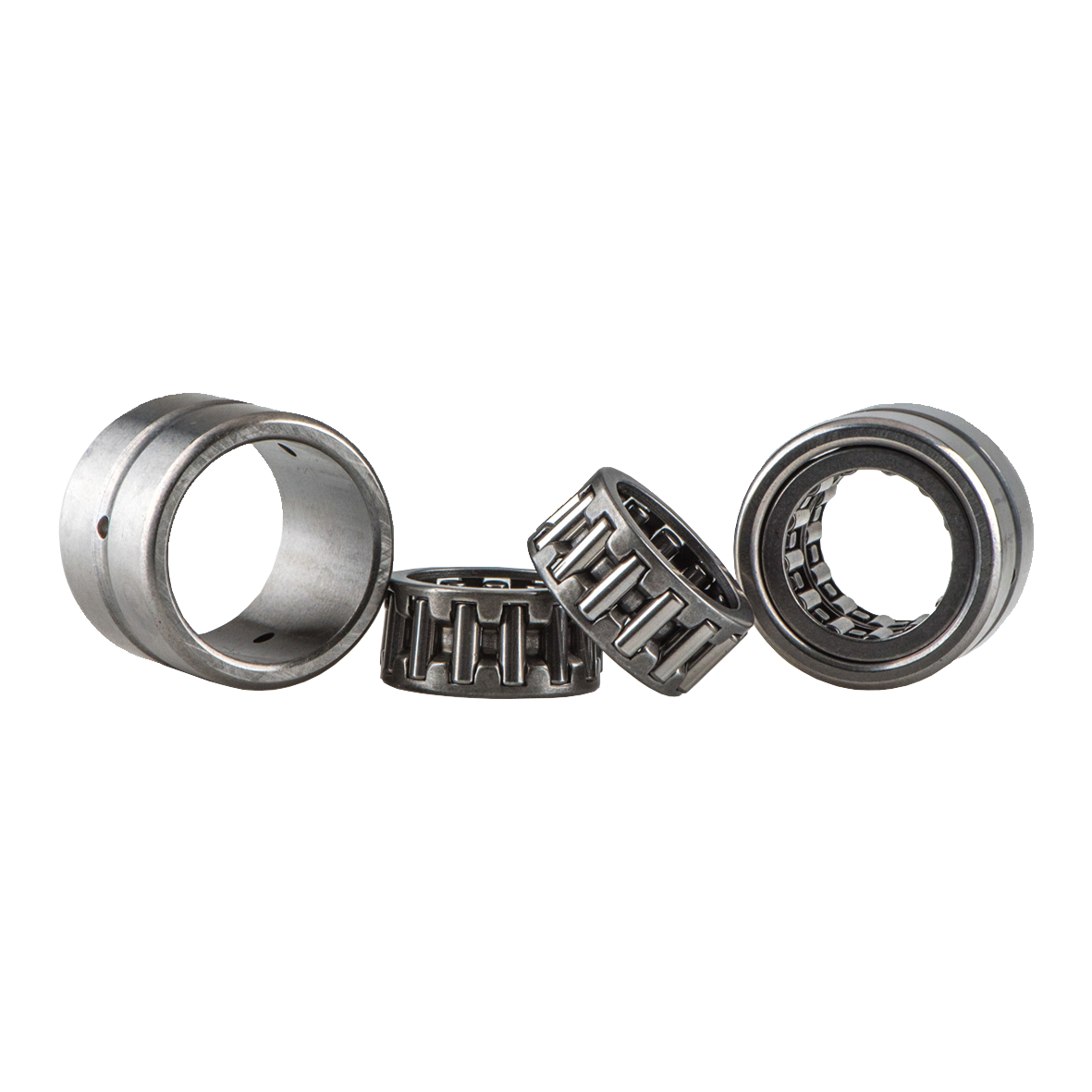

Needle Bearing

Compact structure with high load capacity—ideal for space-limited setups. Needle-shaped design provides high precision, low friction, and excellent weight efficiency.

ISK Bearings looks forward to seeing you!

Visit our booth for on-site consultation and advice.

📌 Date: August 20 (Wed) – August 23 (Sat), 2025

📍 Venue: Taipei Nangang Exhibition Center, Hall 2, 4F

🧭 Booth No.: S830